Making Best Use Of Equipment Durability: Purchasing Premium Undercarriage Parts Solutions

Making Best Use Of Equipment Durability: Purchasing Premium Undercarriage Parts Solutions

Blog Article

Optimize Performance With Durable Undercarriage Parts

In the realm of heavy machinery and tools, the role of undercarriage components is paramount in ensuring optimal performance and long life. The performance and effectiveness of these parts can significantly influence the total procedure of equipment, making the choice of durable undercarriage parts an important choice for managers and drivers alike.

Advantages of Making Use Of Long Lasting Undercarriage Parts

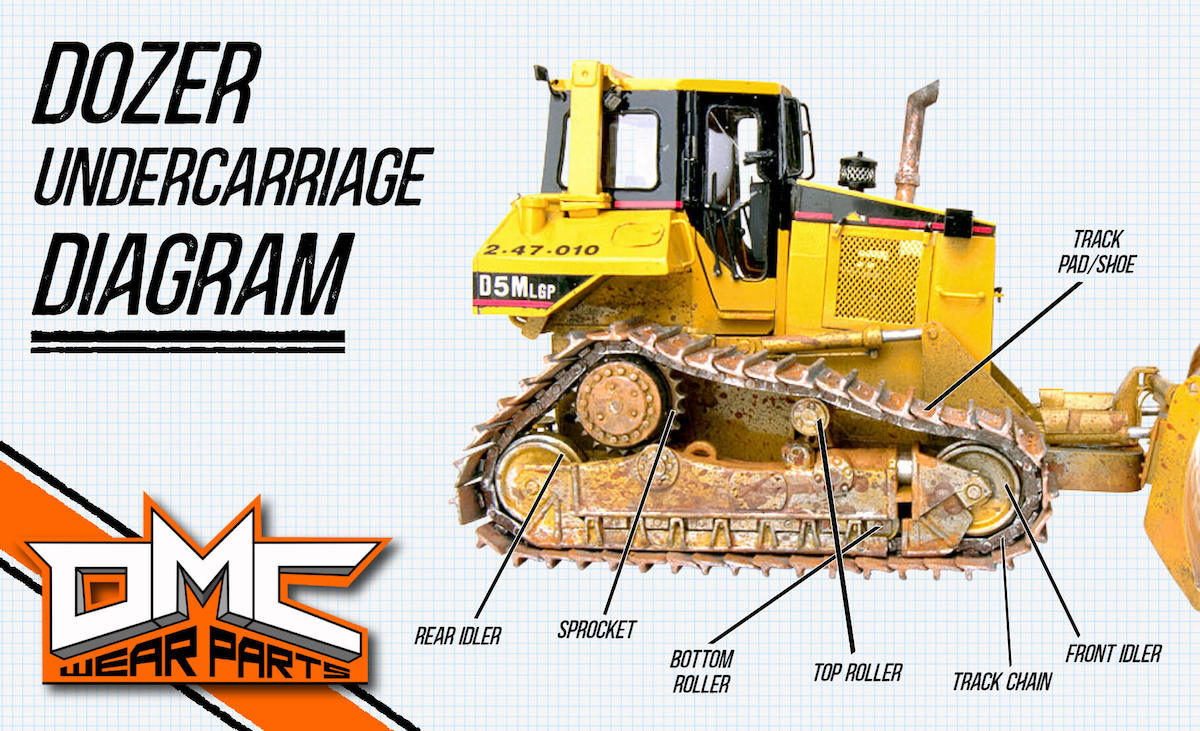

Utilizing sturdy undercarriage components not just boosts the long life of heavy equipment but also lessens upkeep costs considerably. By investing in high-quality undercarriage components, such as tracks, rollers, idlers, and sprockets, tools operators can experience enhanced uptime and boosted overall performance.

Moreover, the long life of hefty machinery is straight connected to the high quality of its undercarriage components. Long lasting components can hold up against the roughness of demanding applications, making sure that the tools continues to be operational for extensive durations. Because of this, drivers can stay clear of pricey downtime and upkeep expenses, ultimately maximizing the return on financial investment for their equipment.

Variables Impacting Undercarriage Toughness

The sturdiness of undercarriage components in heavy machinery is affected by different vital variables that straight effect performance and durability. High-quality materials, such as hardened steel, are vital for standing up to the extreme conditions and hefty lots that undercarriage parts are subjected to - undercarriage parts.

Moreover, ecological factors can have a significant influence on the durability of undercarriage components. Direct exposure to abrasive products, severe temperatures, and harsh working problems can increase wear and tear on undercarriage elements. As a result, choosing undercarriage components that are particularly made to stand up to these environmental difficulties is vital for making certain toughness.

Additionally, the design and engineering of undercarriage components have a direct influence on their sturdiness. Components that are designed to disperse tons equally, lower rubbing, and reduce stress concentrations are extra likely to have a much longer life-span - undercarriage parts. By thinking about these vital factors, equipment operators can make best use of the longevity and performance of their undercarriage elements

Maintenance Tips for Lengthening Undercarriage Life

Executing normal maintenance routines is necessary for extending the life-span of undercarriage components in heavy machinery. To extend the undercarriage life, it is critical to regularly check for deterioration. On a regular basis look for missing or loosened bolts, damaged rollers, or misaligned tracks, as these problems can escalate and create more damages if not addressed quickly. Furthermore, make sure that the undercarriage is effectively lubricated according to maker standards to minimize rubbing and protect against early wear.

An additional important maintenance idea is to keep the undercarriage tidy from dust, rocks, and debris. Buildup in the undercarriage can accelerate wear and rust, leading to pricey repairs. Cleaning the undercarriage after operation in severe problems is advised to stop these issues.

Finally, monitoring and recording upkeep activities can assist in developing an aggressive upkeep routine. Keeping comprehensive records of replacements, repairs, and assessments can offer beneficial insights into the undercarriage's problem and performance in time, assisting in forecasting and stopping potential failings. By complying with these maintenance tips vigilantly, operators can substantially increase the resilience and efficiency of undercarriage parts in hefty equipment.

Choosing the Right Undercarriage Parts

Choosing suitable undercarriage elements is vital for optimizing the effectiveness and long life of hefty machinery. When it comes to picking the best try this out undercarriage parts, there are a number of aspects to take into consideration.

Additionally, thinking about the high quality and track record of the supplier is essential. Selecting trustworthy brands recognized for producing durable and high-performance undercarriage parts can dramatically affect the overall effectiveness and long life of the machinery. Furthermore, making certain that the components are compatible with the machine design and properly mounted is important for optimal performance. By meticulously choosing the ideal undercarriage parts, equipment proprietors can boost productivity, decrease downtime, and prolong the lifespan of their hefty machinery.

Study: Improved Performance With Sturdy Components

Integrating sturdy undercarriage parts has shown substantial enhancements in machinery performance. One instance study involved a building and construction business that upgraded its excavator's undercarriage parts to more durable choices. The company observed a noteworthy reduction in downtime due to undercarriage upkeep, resulting in boosted productivity and price savings. The sturdy parts endured extreme working conditions, decreasing damage dramatically.

In one more circumstances, a mining operation changed the undercarriage parts of its bulldozer with premium, durable choices. This switch brought about an exceptional enhancement in the excavator's ability to move and overall performance. The machine might navigate click this link difficult terrains extra efficiently, bring about improved functional performance and minimized fuel consumption.

Additionally, a logging business bought sturdy undercarriage components for its forestry tools. The updated components exhibited extended life expectancy and boosted resistance to abrasion from rough surface. The company experienced minimized maintenance expenses and enhanced devices uptime, eventually improving its lower line. These study emphasize the concrete benefits of utilizing resilient undercarriage components in maximizing machinery efficiency and long life.

Final Thought

In final thought, utilizing durable undercarriage components can significantly improve performance and durability of hefty machinery. Elements such as appropriate maintenance and picking the best elements play a vital duty in taking full advantage of undercarriage longevity. By applying these techniques, companies can reduce downtime, increase effectiveness, and ultimately reduce operational costs. Situation researches have actually shown that buying sturdy undercarriage components can result in improved total efficiency and productivity in different markets.

The effectiveness and effectiveness of these elements can considerably affect the overall operation of equipment, making the selection of long lasting undercarriage components a vital choice for managers and you can find out more operators alike.Incorporating resilient undercarriage components has actually demonstrated substantial improvements in equipment efficiency. These instance studies highlight the concrete benefits of utilizing resilient undercarriage components in enhancing equipment performance and long life.

In conclusion, making use of resilient undercarriage components can substantially improve performance and durability of heavy equipment (undercarriage parts). Instance research studies have actually shown that spending in resilient undercarriage parts can lead to improved general performance and productivity in different industries

Report this page